Home » Industries »

Our Business Scope In Mine Hoist Producing

Mining Hoists With Frictional Disc Single-rope up to eight-rope hoisting systems nominal frictional disc diameter up to 7 m (22,9 ft) Single-motor and double motor models from 250 kW to 2 x 5500 kW DC and AC drives Static overbalance from 4

Mining Hoists With Frictional Disc

- Single-rope up to eight-rope hoisting systems – nominal frictional disc diameter up to 7 m (22,9 ft)

- Single-motor and double motor models from 250 kW to 2 x 5500 kW

- DC and AC drives

- Static overbalance from 45 kN up to 600 kN

- Payload from 5000 kg (11.023 lbs) to 60000 kg (132.276 lbs)

- Hoisting speed from 3.5 m/sec (19,68 ft/sec) to 20 m/sec (65,6 ft/sec)

Drum Mining Hoists

- Single-drum and double-drum winding systems – nominal drum diameter up to 6,5 m (21,3 ft)

- Single-motor and double-motor models from 250 kW to 2 x 5500 kW

- DC and AC drives

- Static overbalance from 55 kN to 435 kN

- Payload from 4000 kg (8.818 lbs) to 25000 kg (55.115 lbs)

- Mining speed from 6 m/sec (19,68 ft/sec) to 16 m/sec (52,5 ft/sec)

Windlasses

- Single-drum, double-drum and frictional disc windlasses, nominal drum/disc diameter up to 2,5 m (8,2 ft)

- Single-motor from 70 kW up to 250 kW

- Asynchronous drives with a frequency converter

- Static rope-pull up to 130 kN

- Payload up to 7500 kg (16.534 lbs)

- Hoisting speed up to 3 m/sec (9,84 ft/sec)

Individual Drive/Control/Braking Apparatus Systems, Etc.

- DC and AC drives

- Thyristor converter sets VARIANT

- Control distributors with microprocessor systems

- Auxiliary drive distributors

- HV distributors

- Disc braking units

- Electro-hydraulic braking system with a constant braking momentum under the safety-brake mode

- Electro-hydraulic brake systems with two automatically adjusted values of the braking momentum under the safety-brake mode

- Electro-hydraulic braking systems with a constant retardation under the safety-brake mode (independent of the polarity and load)

- Electro-pneumatic braking system

- Model range of electro-hydraulic bearing lubrication system

- Digitalized control panels with integrated central visualization system of operational and faulty conditions

- Air-conditioned soundproof machinist cabins

Remote Monitoring System

- Constant data mining from the hoist controlling system and their transmission to the service center

Mine Signaling Systems

- Redundant network of optical cables

- Microprocessor control

- Non-explosive design

Communication Systems For Transport-Containers

- Enable both phonic and signal communication

- Hoist control from the transport-container is possible

- Non-explosive design

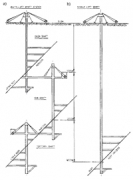

Cages

- One-deck to four-deck design

- Human, material, and mine wagon transport

- High-capacity cages of 1840 x 6250 mm (6 x 20,5 ft) size with extensible or foldaway floors (inside height up to 10 m (32,8 ft)) for the transport of up to 240 people in one go

- Payload from 2500 kg (5.511 lbs) to 16000 kg (35.273 lbs); high-capacity cages up to 23000 kg (50.705 lbs)

Skips and skip-cages

- Double-shell or single-shell design made of high-strength steel

- Custom made types of container covers

- Payload from 1500 kg (3.306 lbs) up to 50000 kg (110.230 lbs)

Tags: mine hosit,mine winder, mine winch, mine windlass