Status Analysis Of Chinese Mine Hoist Manufacture And Our Hoist Features

Mine hoist is a specail transportation equipment and one of four most important and biggest fixed equipments in metalic mine and nonmetallic mine. Usally, we call it mine hoist which has the drum diameter more than 2m or mine winder/mine wi

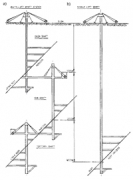

Mine hoist is a specail transportation equipment and one of four most important and biggest fixed equipments in metalic mine and nonmetallic mine. Usally, we call it mine hoist which has the drum diameter more than 2m or mine winder/mine windlass/mine winch which has the drum diameter less than 2m. According to working principle , mine hoist can be divided to single rope winding type mine hoist and multirope friction type mine hoist. Multrope friction type mine hoist can be found specially in deeper shaft.

Nowadays, the running mine hoists in worldwide, the Max. speed can reach 20-25m/s, lifting capacity can reach 50T once, motor power more than 10,000Kw, shaft deepth more than 2000m(multistage lifting more than 3600m). To meet with higher output and different lifting tasks, sometimes will equip several mine hoist on one shaft, for example: Sweden KIRUNA Mine has 12 multirope friction mine hosits at one rectangle shaft tower, and all mine hoists are centralized control.

Evolution of chinese winding type mine hoist and it’s model

Winding type mine hosit evolution has three phases as imitating Russian, development basis on Russian, design.

1953-1958 mainly produced imitating Russian BM series mine hoist;

1958-1966 mainly produced developed imitating Russian mine hoist. JKA series is the improved mine hoist basis on KJ series.

1971.07 began to produce XKT series mine hoist which is design by china self, and changed model to XKT-B series later.

1976 basis on XKT-B series improved to JK series mine hoist which overcome the disadvantages in XKT-B series. JK has been a new type mine hoist by mass production.

Function: Transportation of staffs, material, equipment, etc. between shaft port and underground. It is a key euqipment for whole mine.

Specification: up to 2000m depth.

Bidragon International can provide Multirope Friction and Single Rope Winding Mine Hoist with nominal drum diameter 1.2-4m or bigger as customer’s request.

Function of Mine hoist Drum: Connecting or winding wire rope. Can be divided to two types according to it’s structure: integral, split. Split Mine Hoist Drum is convinient for transportation and installation.

We are mainly engaged in the mine lifting equipment and lifting technology research. Our product design has independent intellectual property rights. Main products are Single Rope Winding Mine Hoist,Shaft Tower type and Floor Mounted Multirope Friction Mine Hoist, Drilling Hoist,Crossing Over Dam Hoist, etc.. Our technical level is leading in domestic. We have made several breakthroughs of chinese mine hoist design and manufacturing:

* China biggest single rope winding mine hoist: φ5 m

* China biggest floor mounted multirope friction mine hoist: φ5.7x4 m

* China biggest shaft tower type multirope friction Mine hoist: φ4.5x6 m

* Chia biggest drilling hoist: φ4 m

* Succeed in design the ship crossing over project of Hunan Zhexi water power station in 2006, and produced china biggest Crossing Over Dam Hoist of JG3-18.

We have produced JK and JKM(D) series mine hoists more than 4300 sets and take 88% market share in china domestic. 2JK-6.3/20 Single rope winding mine hoist, JKMD5.7*4 Multi rope foor mounted mine hoist and JKYB3*2.5xp Hydraulic proof-explosive mine hoist is the biggest model in their series.

The company has strong hoist research, design, development capabilities. Aerial Cableway Institute and Electric Research Institute which are the former standard makers of passenger and cargo aerial cableway undertake research, development and design for hoist. Various types of winding and friction hoist has been standardized, serialized. We take the world mature and advanced electrical control and safety protection system into hoist control and protection such as the Swiss ABB Digital DC Speed Control and VVVF Control, the British CT VVVF which more effectively improve product safety, advanced and reliability, lead the hoist to large, universal and intelligent direction.

Currently, our company has been successful in transfering the advanced and mature computer-controll technology of aerial cableway of passenger into JTP , JKM , JKMD series control system. Therefore the performance in all aspects were upgraded to a new level. So far, we have provide our mine hoist to Xinjiang Malan Coal Mine, Guizhou Zunyi Ferroalloy Group, Hebei Cixian Shenjiazhuang coal mine, Hebei Qianxi iron mine,etc.. Also exported our mine hoist to Bangladesh Bala Pukuliya Mine.

The company consolidated the domestic characteristics of various types of lifting equipment, designed with new structures.Our product features are as follows:

1, Spindle and motor gear unit arranged in the same axis which is convinient for installation and maintenance.and saving about 30% civil construction area.

2,Spindle adopts rolling bearing which is better for installation and adjustment. Spindle with new structure to get better concentricity with the drum. spindle can bear strong impact and has long lifespan.

3, According to user requirements, Drum and Brake disc can be split structure which is easy to transport and the underground installation. Bolts Connection will shorten the installation time and improve accuracy. Split roller installed in the underground, without further processing can meet the design accuracy.

4, Gear reducer has dual power lines and two planetary types. Adopted shunt-type center driven structure can transmiss big power with smooth, low noise, low heat, light weight, long lifespan.

5, The disc brake is sensitive, safe and reliable. Pressure generated by disc springs, hydraulic control, the braking time is less than 0.3 seconds.

6, All machinery control entirely on the operating table, convenient and flexible. Instrumentation is complete, easy to operate.

7, Double drum lifting equipment equiped with quickly gear clutch hydraulic control device, rope adjustment can be realized easily on control platform.

8, The electric control device has a common type and PLC-control type. According to user requirements,we provide DC drive or Variable Frequency Drive.

Tags: mine hoist, mine winder, mine windlass, mine winch